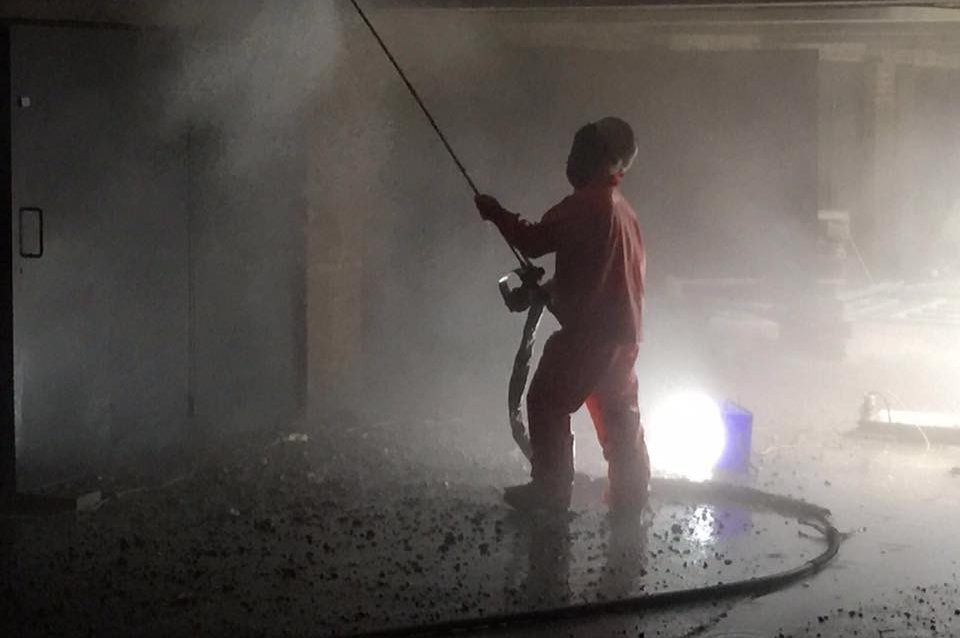

HYDRODEMOLITION

SABRE JETTING SERVICES IS COMMITTED TO BEING THE NUMBER ONE CONCRETE REMOVAL & HYDROBLASTING CONTRACTOR IN THE UNITED KINGDOM.

What is the process known as hydroblasting? This is known by a number of names (including concrete hydrodemolition,) but the process and effect is the same. It involves the technique of using a water jet which is set to high pressure to allow concrete to be broken up and removed. Hydroblasting is often a term used to describe what happens during this process as concrete removal is undertaken. In order to provide effective hydrodemolition services we have invested heavily in our workforce and the equipment that we use. Our operators are highly trained including specialist in-house training which is not available elsewhere. This makes us one of the best hydroblasting companies around Our operators also have access to an extensive fleet of Hammelmann jetting units which are unrivalled in terms of capability and reliability for the hydrodem process.

a full hydrodemolition package on every project

The result of all this experience and high quality equipment for our clients is shorter programming, lower costs and maximum safety awareness, during the hydro demolition of concrete. We are happy to offer a full hydrodemolition package on every project, including provision of water and, treatment of the run-off water. All of our pumps are sound attenuated, reducing the noise impact of our operation. and we We are also able to provide sound attenuation blankets to encapsulate the jetting enclosure where required.

Sabre Jetting Services’ first hydrodemolition contract was completed successfully in 1989 for Edmund Nuttall. Since then we have grown and expanded into the large scale industrial hydroblasting company we are today. We now employ twelve operators who are permanently engaged in concrete demolition and removal, completing hydroblasting contracts ranging in value from £850 to £500,000 making us the countries most experienced concrete hydrodemolition contractor.

Due to the ability of our operatives, we are not limited to one type of hydrodem, and are able to undertake concrete removal projects of any nature ranging from intricate work such as bearing removal, to bulk projects such as hydroblasting of parapets. The skills of our workforce have been developed due to the many highly technical midland links contracts we have successfully carried out as a key member of the area 9 partnering scheme.

If you are interested in our concrete high pressure waster cutting service, then get in touch with us today to talk about your requirements.

WHAT IS HYDRODEMOLITION?

Hydrodemolition is the controlled removal of concrete using high pressure, high speed water has several advantages over traditional air tool, machine mounted breakers.

- Minimal vibration to the operator

- No loose or damaged concrete on the edge of breakout area

- No damage to steel reinforcing

- Removal of concrete around dense reinforcing (impossible using air breakers)

- Thorough washing / self cleaning of breakout area

The use of hydrodemolition seems to becoming more widespread amongst the construction industry, particularly within the civil engineering sector. The reasons listed above are the main factors for the increase in awareness of what is now a growing industry.

SAFETY

When carrying out hydro-demolition safety is of paramount importance. At Sabre Jetting Services we take the safety of our operators and anybody else that could come into contact with the operation extremely seriously. All of our equipment and PPE is serviced, tested or replaced using standards well above the manufacturers recommendations. We can guarantee our customers we only use the best equipment and PPE, identified using the vast experience gained over the last 30 years.

As leaders in the specialist industry of hydro-demolition we have developed our own safety procedures following the Water Jetting Association code of practice. Our POSH Procedures are a reminder to our operators of their duties on every site and will ensure that every single job we carry out is setup in the optimum way to ensure minimum risk. The acronym POSH stands for, Positioning of the jetting unit, Operation of the jetting unit, Seeing the jetting enclosure and Hearing the jetting operation. Keeping in mind these four key responsibilities means that our operators are perfectly prepared to deal with any potential emergency.

WORK WITH US

We are always happy to make new connections,

so if you wish to work with us or simply want more information regarding Hydro Demolition, Surface Preparation and Tank Cleaning